SMT inspection systems are essential for detecting and resolving any manufacturing defects that may arise during the production process. These systems must be capable of identifying defects such as misalignment, insufficient solder joints, and incorrect component placement, to ensure that the final product is reliable and high-quality.

One effective method of inspecting SMT components is by using a microscope inspection system. Microscope inspection systems provide high magnification and high-resolution images of the components and the soldering points. This system offers an exceptional level of detail and allows manufacturers to spot flaws that are not visible with the naked eye.

Another popular method of inspecting SMT components is using automated optical inspection (AOI) systems. AOI systems use cameras and software to provide quick and accurate inspections. This method not only speeds up the inspection process but also eliminates the possibility of human error.

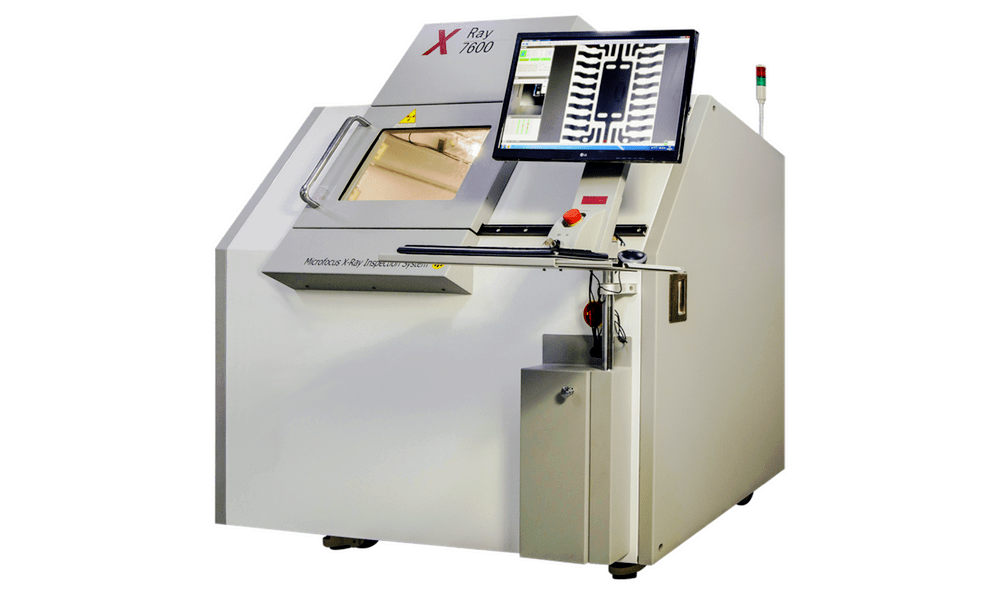

In addition to AOI systems, X-ray inspection systems are often used to inspect components that are not visible from the surface, such as BGA (ball grid array) components. X-ray inspections provide images of components from different angles, allowing manufacturers to detect defects that may not be visible from a single angle.

It is essential to choose the right SMT inspection system for your needs. The right system will depend on the size of your manufacturing operation, the volume of products you produce, and your specific requirements. Whether you choose a microscope inspection system or an automated inspection system, make sure that it meets your needs and provides accurate and reliable results.

In conclusion, the importance of SMT inspection systems cannot be overstated. These systems are critical to ensuring that your components are of top quality, reliable and meet the requirements of your customers. Whether you are just starting out or have been in the industry for years, investing in an SMT inspection system is a must. So, take the time to research and choose the right system for your needs, and you will reap the benefits of high quality and satisfied customers.